The numbers speak for themselves

What the numbers have to say: we’re experienced in the field, committed to safety, and prioritize good customer service.

Manufacturer Lic.# MF1279666 | Dealer Lic.# DL1279666 | CSLB CA. Lic.# 992118-B | DIR Reg.# 1000012108 | NAICS: 321991 & 532490 | UNSPSC: 95140000 | SIC CODE: 2451 & 7359 | SINs: 332312

WMBE# 22000769 | DBE/SBE# 51294 | SB# 1795512 | WBENC# 2301591 | WSOB# 230946

Modular Construction is a resource-efficient, off-site delivery method to construct code-compliant buildings in a quality-controlled factory setting.

Prefabricated buildings, prefab, factory-built, modular buildings: All these words refer to the same process of manufacturing a building off-site and installing it on-site. The prefabricated construction process offers design and planning flexibility: it can be either temporary or permanent, small or large, contemporary or traditional, single-story or multi-story, an individual building, or multiple buildings arranged in a complex or campus.

Modular construction creates a high-quality building project, built to all applicable codes in far less time than traditional site-built construction, with ‘green’ consideration in terms of sustainable building materials, labor efficiency, reduced waste, reduced site disruption, and reduced transportation emissions.

SKC’s modular delivery process consists of 8 steps from concept to completion:

More detailed descriptions of each step are featured in the following step by step explanation below.

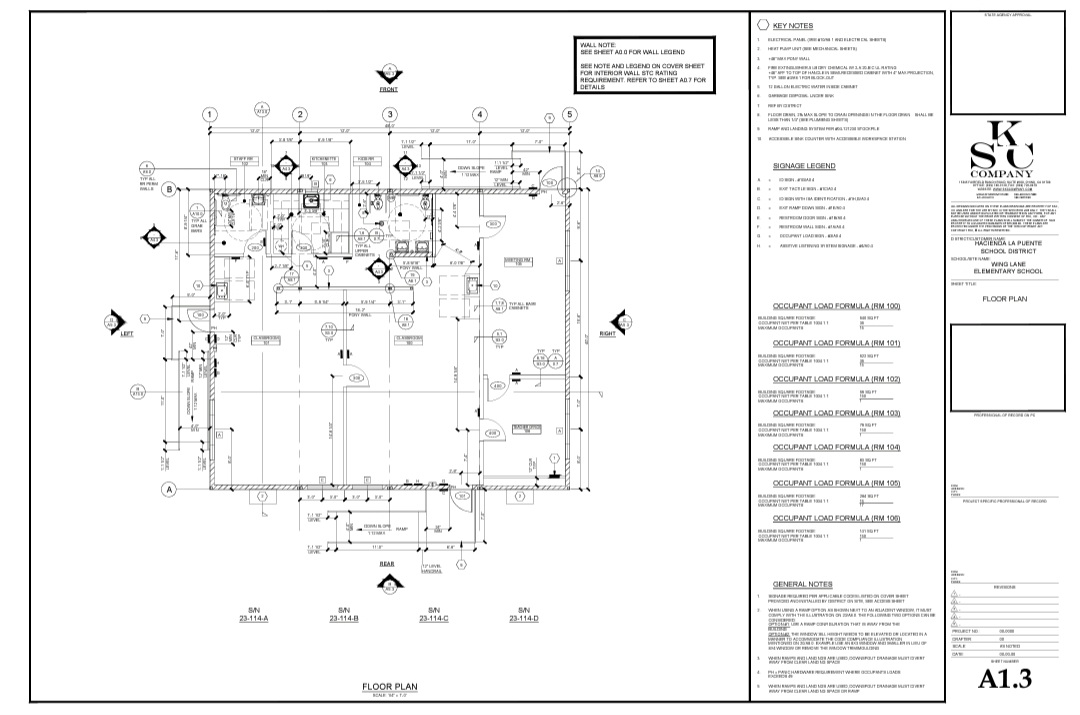

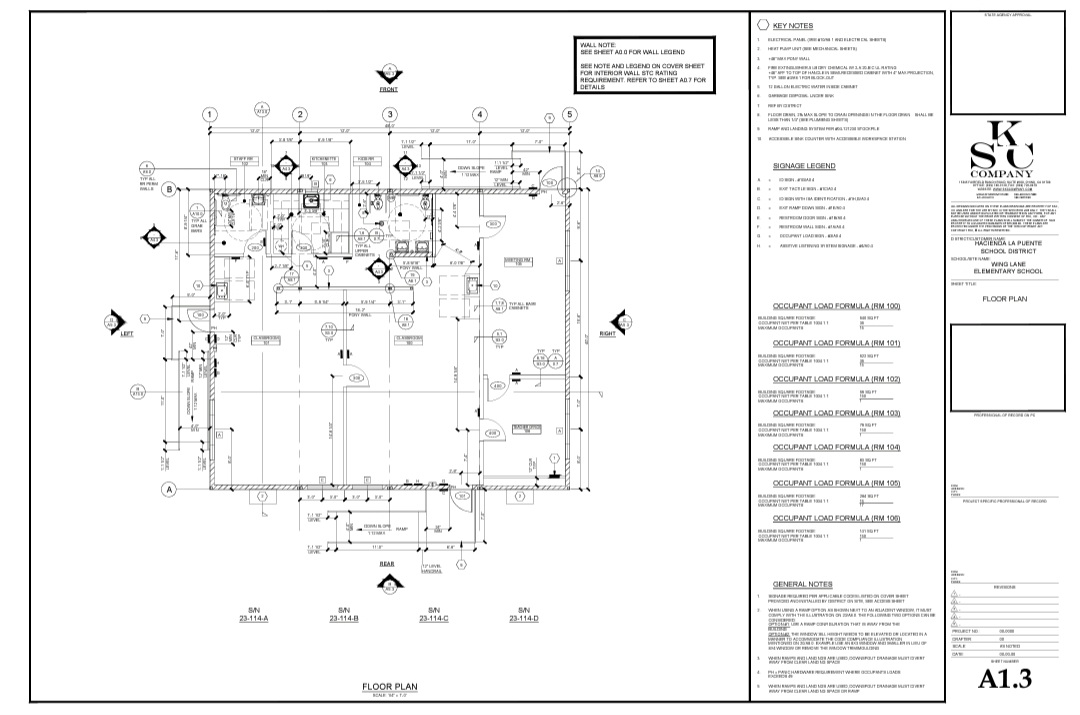

The design phase of the modular building process creates a description of the building, usually represented by detailed plans and specifications.

Our Design, Project Manager, Estimating and Sales team conduct a thorough customer consultation to gather the information required to develop the building plan. Some of the building parameter questions include:

This is where we identify what the customer is looking for whether it’s a cost-driven utilitarian building or a modern energy efficient modular building. Once this information has been gathered SKC’s design team will produce the ideal modular building design to fit the customer’s needs.

Each building design goes through the SKC engineering department for an engineering review. Like site-built structures, modular buildings are subject to a series of national, state and local building codes that ensure the building meets a set of standards for safety and performance.

State-level building codes can be superseded or augmented by local building code requirements, such as the High-Speed Wind Zone code adopted by many coastal counties.

During the building review process, the SKC engineering department confirms the design proposal meets all applicable building codes. For example, in the State of California all industrialized modular components are required to comply with the following codes:

2022 CBC

After our engineering review has been completed the engineering documents are sent for approval from an independent third party engineering review.

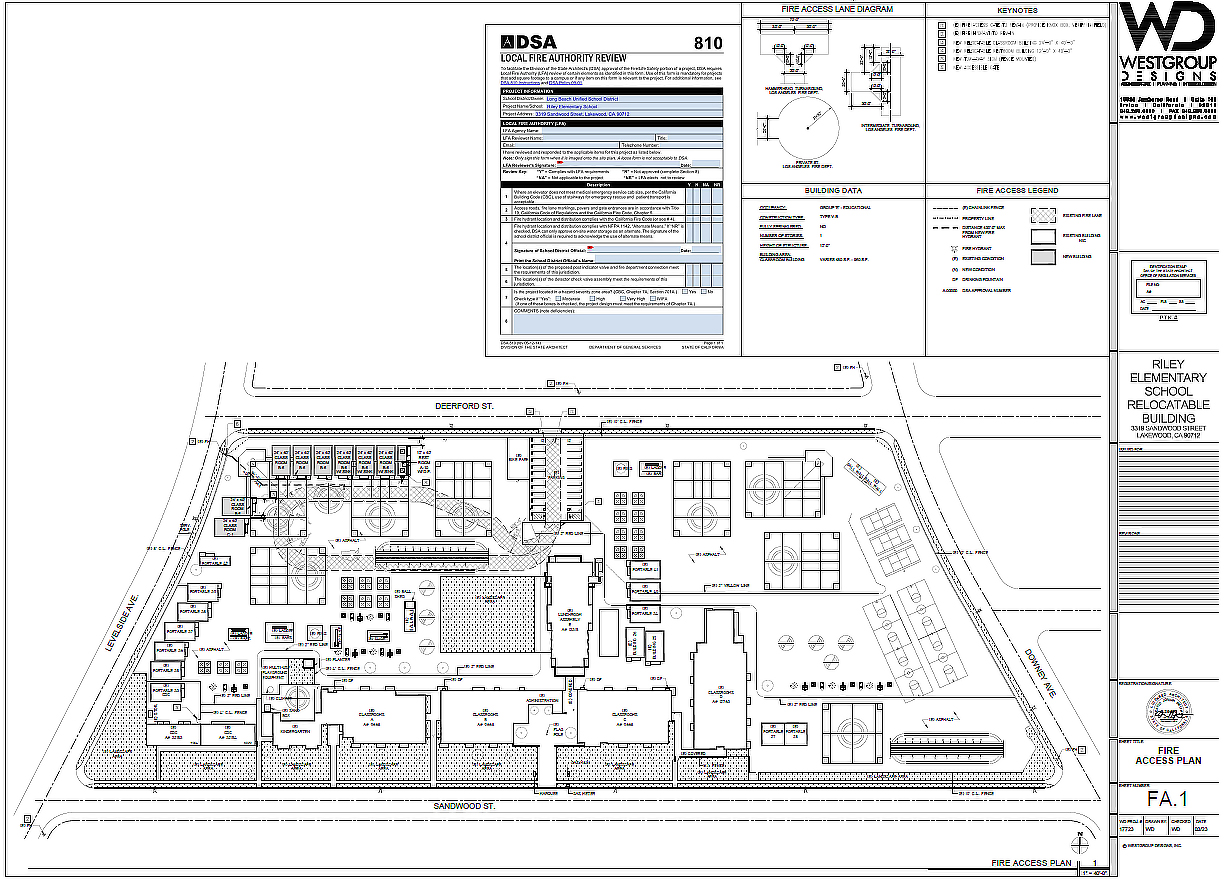

The building owner is ultimately responsible for securing building permits and paying DSA fees for work on their property. In practice, most building owners appoint the general contractor as an authorized representative so the contractor can obtain the required permits. The building owner is advised to confirm that the general contractor has secured the proper building permits for their project. Failure to obtain the proper permits can result in significant fines, penalties, and even removal of unauthorized construction.

One of the advantages inherent in modular construction is that the site development and building foundation are prepared while the modules are being fabricated at the manufacturing facility and transported to the job site.

The site development and building construction processes happen concurrently instead of sequentially like site-built construction. Projects are developed in a variety of geographic settings and typical site development includes:

There are two primary modular building foundation classifications; on grade and raised concrete or wood foundation. An on-grade foundation is generally for permanent installations and is more expensive. A wood foundation can be used for temporary or permanent structures, it is less expensive to install, and it is more cost effective to relocate the building later while causing minimal site disturbance.

The fabricated modules are shipped over the road by carriers that specialize in modular building transportation. In most U.S. jurisdictions building shipping limitations are 16’ in width and between 70’ & 90’ in length per module. SKC Standards are 12’width by 40’ length.

The scope of the project and the size of the modules determines how the project is transported to the job site. For large projects, like a man camp that consist of dozens of modules, the delivery is staged in phases so that our PM or Vendor can prepare coordination and install the modules in a logical sequence.

A general contractor, often one specializing in modular construction, will install the modules, complete any on-site finish out and make the final utility connections.

The choice of building foundation determines how the building will be installed. Permanent, semi-permanent and on grade foundations will require the modules to be set with a crane.

Raised wood foundations, typically used for temporary buildings, allow the modules to be set in place through simple mechanical methods.

With the modules in place final finish out of the interior and exterior proceeds. Finish out can include electrical and mechanical system connection between modules, stairs, wheelchair ramps, skirting, exterior siding, trim and utility connections.

SKC COMPANY met the schedule, was responsive to our requests, dealt with all project related issues in a professional manner and delivered a high-quality product. We look forward to working with SKC on future projects.

If you have any questions and or need additional information, please feel free to contact our office. Thank you.”

The staff consistently produced outstanding work and was responsive to the needs of our project team. We are pleased to recommend SKC COMPANY to others and look forward to working with them on future projects.”

© 2023 – A Sean Khan Consulting Company, Inc. (dba) SKC COMPANY a Registered Trademark. All Rights Reserved.